Yale School of Nursing (YSN) recently received 1,000 injection-molded face shields, the result of a collaboration with Cisco.

John Marshall, Distinguished Engineer and founding member of the Cisco volunteer team, said the partnership with YSN began in the Department of Computer Science. Assistant Professor Robert Soulé was working with the Cisco Research Center on a grant proposal, and during one of those discussions the technology company mentioned its plans to 3D print personal protective equipment (PPE) for emergency use during the COVID-19 pandemic.

Ariadne’s skein next led to Vince Wilczynski, Deputy Dean of the Yale School of Engineering and Applied Science and Director of the Center for Engineering Innovation & Design (CEID), the primary maker space on campus. Wilczynski was deeply involved in the university’s COVID-19 response, a coordinated effort that includes YSN Dean Ann Kurth ’90 MSN, PhD, CNM, MPH, FAAN.

“YSN was already collaborating with Vince and the CEID to strategize solutions for frontline providers fighting COVID-19,” Kurth said. “We have so many faculty, alumni, students, and preceptors in frontline clinical positions, and we know what a difference PPE makes in terms of combating viral transmission. We were thrilled to partner with Cisco on the face shields project and gratefully look forward to distributing the supplies for our student and faculty community.”

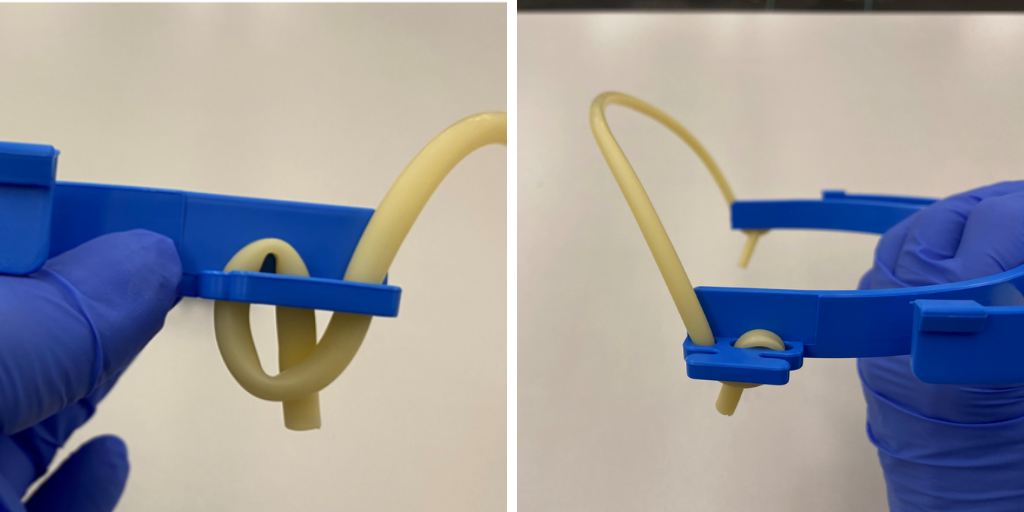

From 3D Printing to an Injection-Molded Design

Marshall explained that Cisco sites started 3D printing face shields with their local maker communities. Cisco started delivering completed face shields in early April, a time of acute shortages for all kinds of PPE and component materials.

“In addition to the Cisco-wide 3D printing activities, our team started to work on the moldable face shield design. As part of the design process, we evaluated a number of NIH-approved face shield models. A new design was synthesized to provide the ability to use alternate materials for the elastic strap as well as simplified construction to facilitate efficient injection molding,” Marshall said. Cisco then contributed its design to the open-source community supported by the NIH 3D Print Exchange. Check out the final design here.

In its best week, Marshall said Cisco produced about 10,000 face shields. More than 150 company volunteers donated approximately 650 hours of their time to complete the 10,000 units. The assembly took place across four sites in California, North Carolina, Ohio, and Texas.

“It was really great to see the level of community support, and we’re glad that we could contribute,” Marshall said.

YSN Distributing PPE

Kurth said the face shields will be an important part of supporting PPE needs of students for clinical sites that require that as health agencies begin re-opening to students.

YSN has facilitated distribution of PPE supplies several times during the COVID-19 pandemic. Xiangya Hospitals and Schools of Medicine, Nursing, and Public Health gifted 1,000 N95 masks, 200 protective surgical gowns, and 100 pairs of goggles—asking that Yale-China help speed these to their friends at Yale—as a thank you for many years of support.

YSN staff and faculty also helped hand out face coverings for the general public on West Campus with Masks for CT, supplying protective masks to the local communities of West Haven, Orange, and the greater New Haven region.